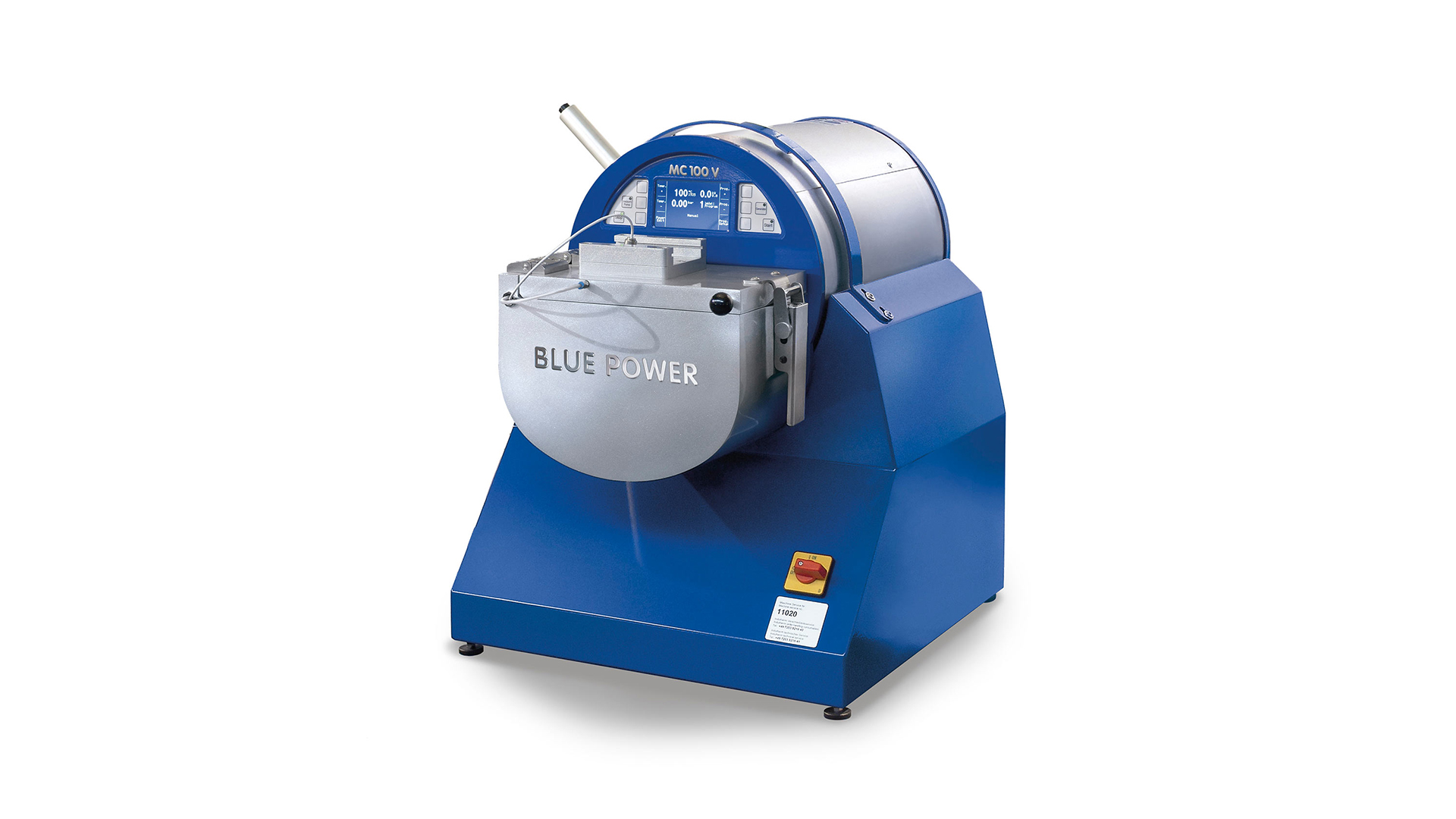

The MC 100 V table-top casting machine - 2000° C plus capacity

The MC 100V can be used for a wide range of materials such as gold, silver, bronze as well as refractory metals such as platinum, palladium and steel.

- Very convenient and safe to operate, short training time

- 8 kW (3 x 400 V) induction generator for quickly reaching the melting temperature

- High capacity: crucibles with a casting volume of up to 450 g Au 18 ct or 500 g Pt, for flasks up to Ø 100 mm x 120 mm H

- Thorough mixing of the melt through low-frequency induction tuning

- Melting under vacuum or inert gas to prevent oxidation

- First-class mold filling due to overpressure up to 3 bar (casting under vacuum possible)

- Optical radiation thermometer for temperature measurements up to 2,000° C

The high demand for our MC 16 and VTC 200 V high-temperature tilting casting systems motivated us to develop the MC 100 V: many users wanted the compactness of the MC 16 but needed more capacity - but not as much as the large VTC 200 V offers. With the MC 100 V, we have closed this gap and can offer you a small high-tech system that combines the best of both alternatives: it is based on the space-saving design and the ingenious swiveling mechanism of the small MC 16, but offers numerous highlights of the much larger VTC system.

The latest generation of generators

The MC 100 V is equipped with the latest generation of induction generators, which have been specially developed for this type of housing and work extremely efficiently. It is conveniently and precisely controlled via a user-friendly system with LCD full text display and program control.

Award-winning vibration technology - a first in this class

Our multiple award-winning and patent-pending vibration process is being used for the first time in such a compact moulding machine. Casting with vibration ensures better mould filling and produces castings with higher and more uniform density, greater elasticity and extremely reduced porosity. Especially when casting platinum or palladium, the vibration technology is a convincing alternative to the otherwise frequently used and relatively susceptible centrifugal systems.

Data Overview of MC 100 V

■ standard equipment, ○ optional, - not available| MC 16 | MC 20 V | MC 60 V | MC 100 V | MTC 100 V | |

|

Power

|

|||||

| Temperature max. | 2000° C | 2000° C | 1300° C | 2000° C | 2100° C |

| Power max. / electrical connection | 3,5 kW (230v single phase) | 3,5 kW (230v single phase) | 3,5 kW (230v single phase) | 8 kW (3x400v) | 8 kW (3x400 V) |

|

Capacity

|

|||||

| Crucible Volume | 100g Au 18 ct 110g steel 200g Pl | 100g Au 18 ct 110g steel 200g Pl | 450g Au 18 ct 300g Ag 935 |

450g Au 18 ct 250g steel 500g Pl | 450g Au 18 ct 250g steel 500g Pl |

| Volume ceramic crucible | 30 ccm = 600 g Pt / 250 g steel | ||||

| For use of molds | up to ø 30/50/65/80 mm x 80 mm h | up to ø 30/50/65/80 mm x 80 mm h | up to ø 80/100 mm x 120 mm h | up to ø 80/100 mm x 120 mm h | bis ø 100 mm x 150 mm H |

| Volume graphite crucible | 25 ccm = 450 g Au 18 ct | ||||

|

Operation and Control

|

|||||

| Control system | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout |

| Turbo Pressure PLUS system | ■ | ||||

| Maximum pressure | 3 bar | ||||

| Automatic vacuum function | ■ | ■ | ■ | ■ | ■ |

| Automatic overpressure function | ■ | ■ | ■ | ■ | ■ |

| Casting also under vacuum only | ■ | ■ | ■ | ■ | |

| Vacuum/Inert gas overpressure | ■ | ||||

| Function washing by inert gas | ■ | ■ | ■ | ■ | ■ |

| Vacuum or overpressure after casting | –1 up to +2 bar | –1 up to +3 bar | –1 up to +2 bar | –1 up to +3 bar | –1 up to +3 bar |

| Temp. measurement by thermocouple | up to 1.300° C, ■ | ||||

| Vibration system | - | ■ | ■ | ■ | ■ |

| Supply: cooling water, inert gas argon or nitrogen | ■ | ■ | ■ | ■ | ■ |

| Temperature measurement/control | ■ up to 1.300° C, ○ up to 1.600° C | ■ up to 2000° C | ■ up to 1300° C | ■ up to 2000° C | ■ bis 2100° C |

| Temperature measurement equipped with an optical pyrometer | - | ■ | - | ■ | up to 2000° C |

| Temperature measurement equipped with a dual wave pyrometer | - | ○ | - | ○ | ○ |

|

Quality Assurance

|

|||||

| RS 232, Ethernet, USB interface, diagnostic system | ■ | ■ | ■ | ■ | ■ |

| GSM-modem for remote service | ○ | ○ | ○ | ○ | ○ |

|

DMS

|

■ | ■ | ■ | ■ | ■ |

| InduthermCloud | ○ | ○ | ○ | ○ | ○ |

| iThermControl | ○ | ○ | ○ | ○ | ○ |

|

Accesories

|

|||||

| Vacuum investment mixer Indumix 2+ | ○ | ○ | ○ | ○ | ○ |

| Vacuum investment mixer Indumix 3+ | ○ | ○ | ○ | ○ | ○ |

| Furnace AK 20 | ○ | ○ | ○ | ○ | ○ |

| Furnace AK 50 | ○ | ○ | ○ | ○ | ○ |

| Sand blasting cabinet | ○ | ○ | ○ | ○ | ○ |

| Vacuum pump up to 8 m³ /h | ○ | ○ | ○ | ○ | ○ |

| Vacuum pump up to 21 m³ /h | - | - | ○ | ○ | - |

| Vacuum pump | ○ | ||||

| Floor unit | - | - | - | ○ | - |

| Water chiller | ○ | ○ | ○ | ○ | ○ |

Other Advantages of MC 100 V