Continous Casting

Continuous casting

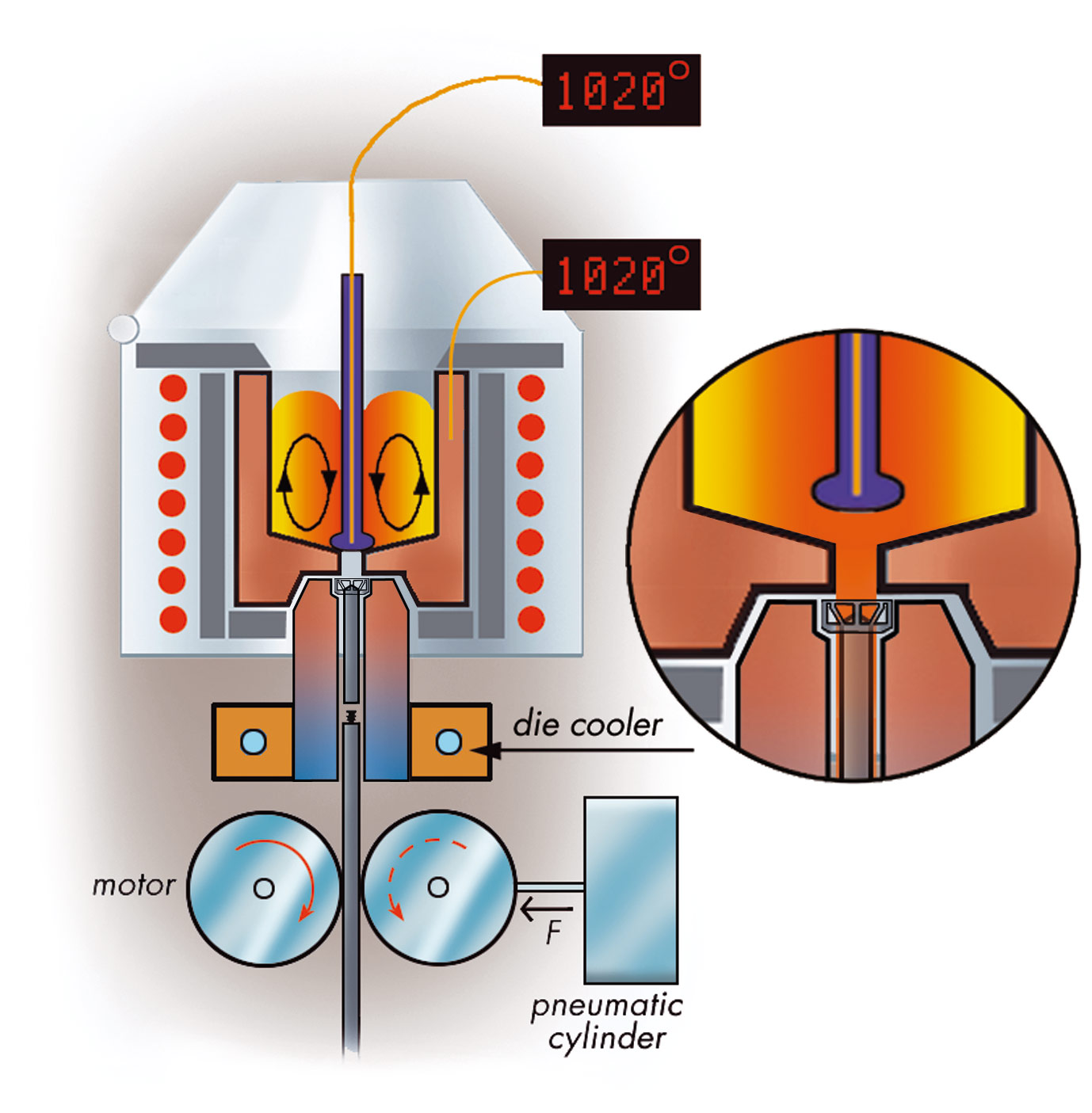

The function principle of our continuous casting machines is based on similar ideas as our vacuum pressure casting machines. Instead of filling the liquid material into a flask you can produce (draw) sheet, wires, or tubes by using a graphite die.

Therefore, we use a die cooler that cools down the material below solidification point. The so-called drawing unit consists of a microprocessor-controlled motor that pulls out liquid material in programmable steps. The drawing time, the stop time and the optional reverse time are variable.

This way you can produce your required semi-finished material without any air bubbles or shrinking porosity. Optional tools as hydraulic cutters, bending units or coiling systems enhance the versatility of the machine. All continuous casting machines operate on a lower frequency than usual on the market.

This low frequency leads to a very high penetration of the electromagnetic field in the liquid melt. This physical effect called mixing or stirring effect prevents a sedimentation of materials with a higher specific weight e.g., gold in the liquid bath. The material is in most of the cases homogeneous up to 10th of a thousandth.

All continuous casting machines operate on a lower frequency than usual on the market. This low frequency leads to a very high penetration of the electromagnetic field in the liquid melt. This physical effect called mixing or stirring effect prevents a sedimentation of materials with a higher specific weight e.g., gold in the liquid bath. The material is in most of the cases homogeneous up to 10th of a thousandth.

Indutherm continuous casting machines: more flexibility, lower costs

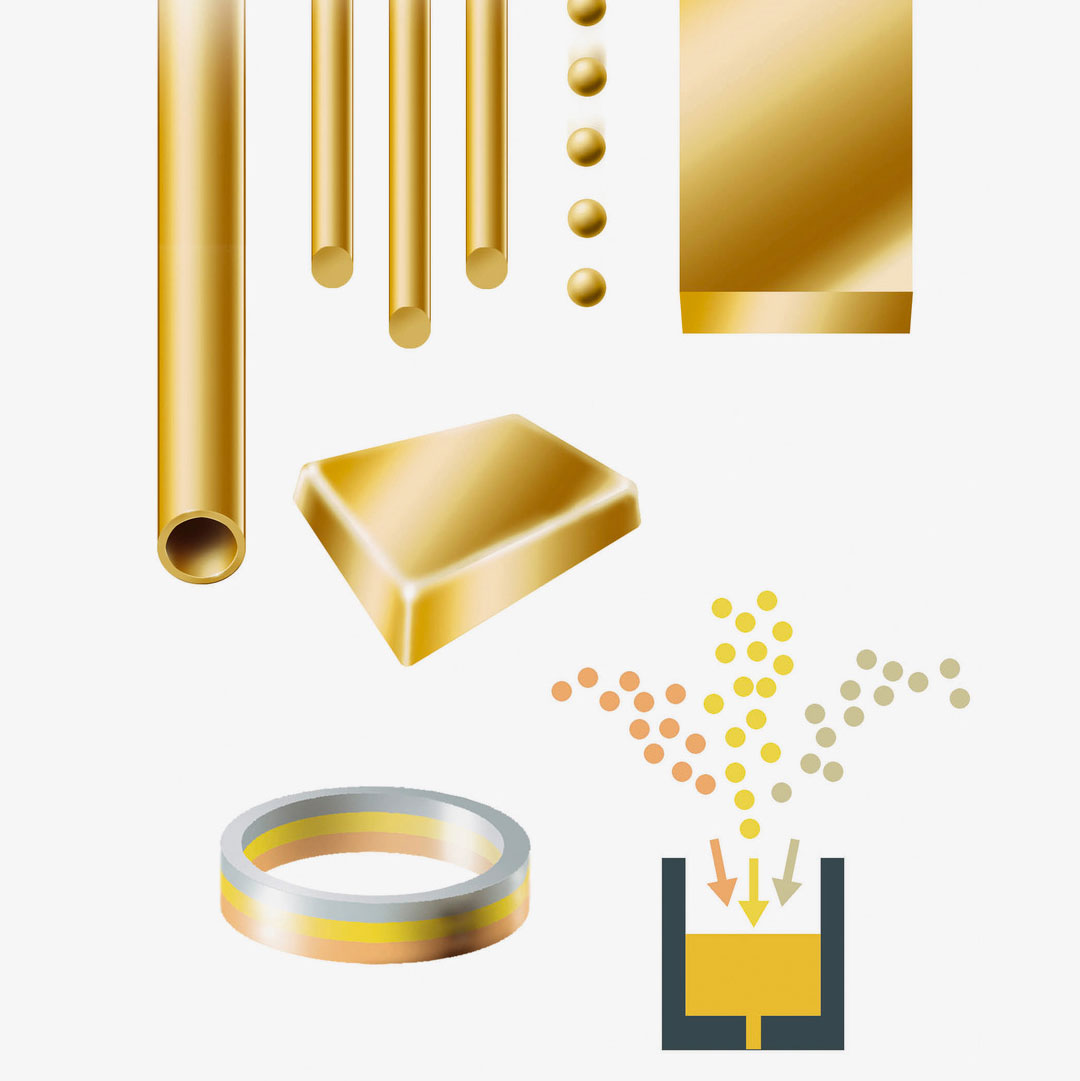

With an Indutherm continuous casting machine, you can produce your own alloys or semi-finished products in different shapes and sizes in the shortest time:

Wires, sheet and tubesWires or tubes up to ø 90 mm, sheet up to 130x40 mm. Numerous options for cutting or sawing into sections during casting, for bending or coiling. VCC series with inert gas/vacuum system for the melting chamber.

Granuleswith the easy to install granulation tank

Production of flakese.g., for refining applications

Multi-layer rings and braceletswith the optional sintering/diffusion bonding kit

Casting into ingot moldsor any other molds

What material ever you want to produce, the use of a continuous casting machine can reduce your investment for material in storage considerably. Your processes will get faster, more flexible, and more efficient.

Unique vacuum system

For highest quality of semi-finished material:To reduce the risk of oxidation during melting and during drawing, we focus on avoiding oxygen contact and on fast reduction of the temperature of the drawn material.

Features for fast temperature reduction:- Cooling water temperature measurement and automatic flow control

- Optical temperature measurement in the center of the die

- Die cooler

- Additional secondary cooling system at the outlet

- Vacuum system for the melting chamber – uniquely available for Indutherm continuous casting machines (VCC versions)

- Feeding system for re-charging without oxygen contact and with constant vacuum in the melting chamber

- Inert gas system for the melting chamber

- Inert gas flushing at the die

- Optical die temperature measurement

All these measures are ideal especially for alloys containing copper such as red gold or for silver as these materials tend to oxidise easily.

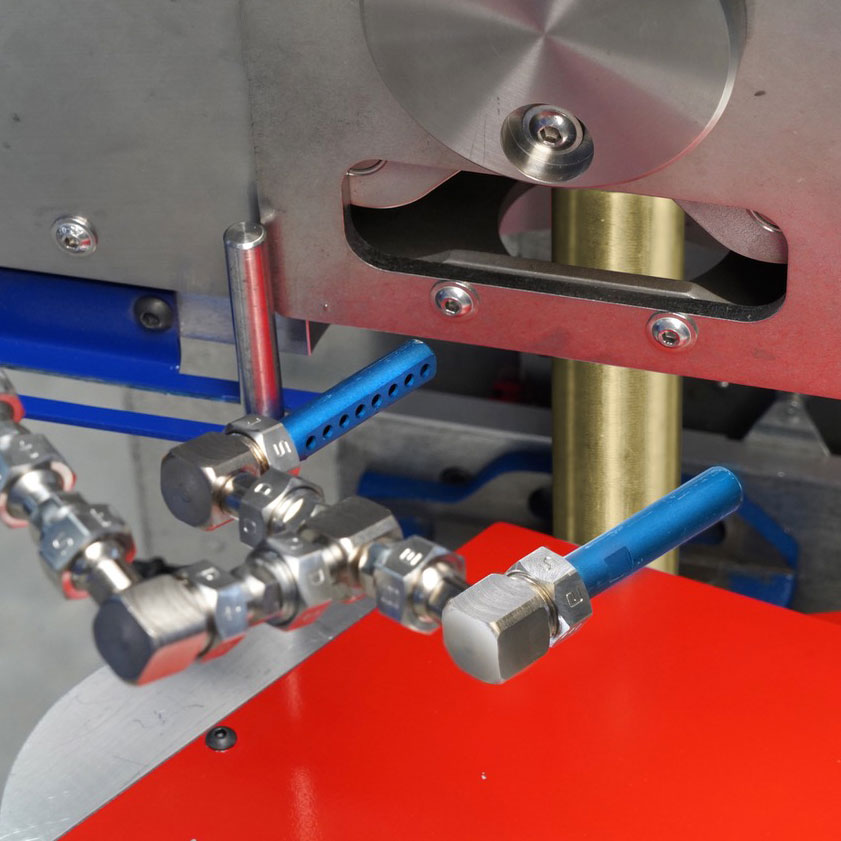

Quattro Drive System

On each of our continuous casting machines, the material is drawn off by motor driven and pneumatically pressed-on feed rolls. A bar end control sensor stops automatically when the molten material is spent. The optional Quattro Drive drawing unit with four instead of two motor driven feed rolls produces smoother tubes and sheeting with reduced marks of transportation.

Granulation tank and flake kit

The easy to install granulation tank and the flake kit make each CC machine even more versatile. The major applications are

- Preparation of alloys or alloy components

- Preparation of alloys from components

- Cleaning up of already casted metal

- each under inert gas atmosphere or vacuum.

Sintering kit

Sintering/diffusion bonding is the optimum process for producing multi-coloured rings, mostly sold as wedding rings, or bracelets. Metals are processed under pressure and at temperatures below the solidification point. The pressure is generated pneumatically and not mechanically via a threaded spindle. This means that there is no risk of graphite parts breaking because of heat expansion.

Bar casting kit

The bar casting kit is developed for casting defined quantities of your alloy into ingot moulds or into any other moulds. The program control recognizes the applicated equipment and provides the suited parameter settings on the display.

Bending unit

Using the bending unit attached to the bottom drawer, the material can be bent without mechanical force on the die.

Pneumatic cutter

The hydraulic cutter is suited for cutting wires into pre-defined sections.

Flying saw for shorting during drawing

The swivelling electric moves synchronously with the drawn bar or tube. This way you can cut your material into defined sections during drawing. You don’t need to stop the continuous casting process when maximum length is reached.

You can find us here!

Through clicking of this button the site will connect to the Open Street Maps - Servers. More at "Open Street Maps" on our Privacy Page.