AUS 500, the new Atomizer solution – from alloy creation to powder within 1 hour

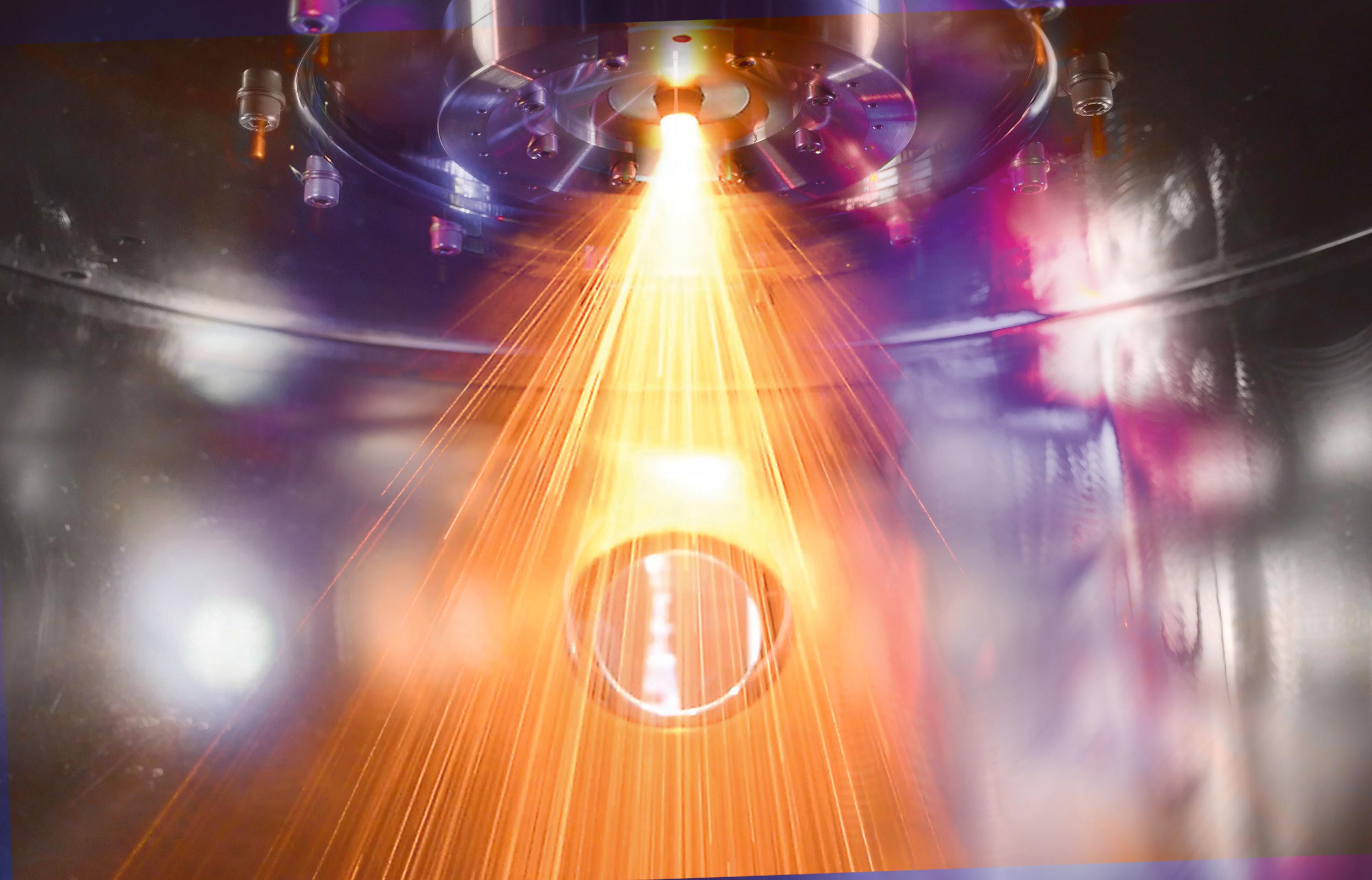

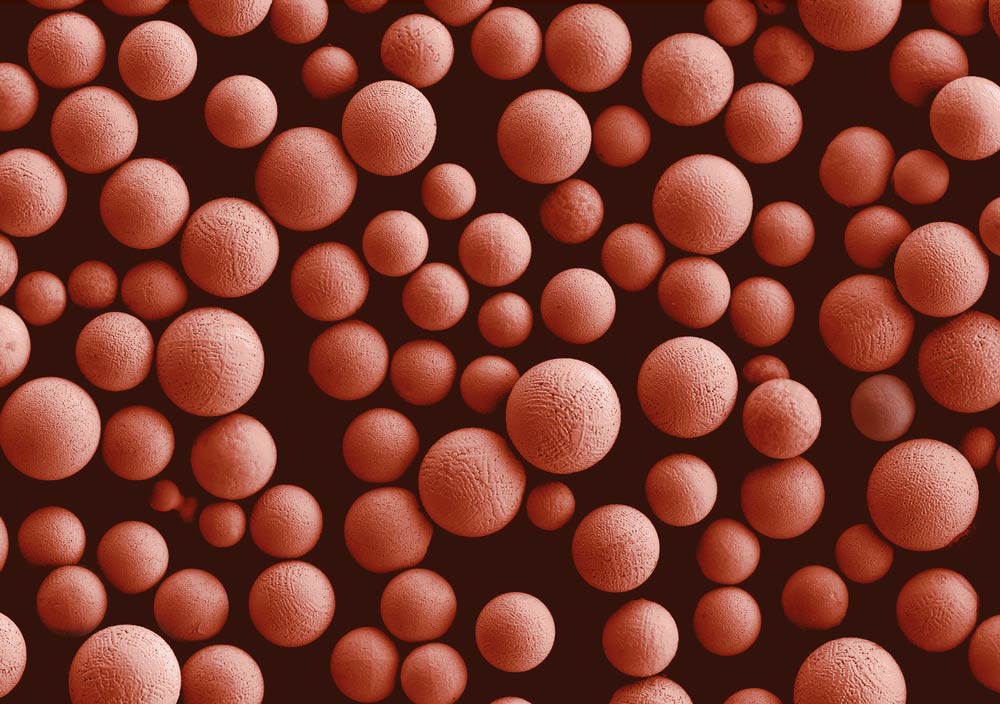

The Ultrasonic Atomizer Unit enables almost anybody to produce small batches of high-quality, spherical powder for the same target application as gas atomized powder at an affordable price and without having a complex infrastructure.

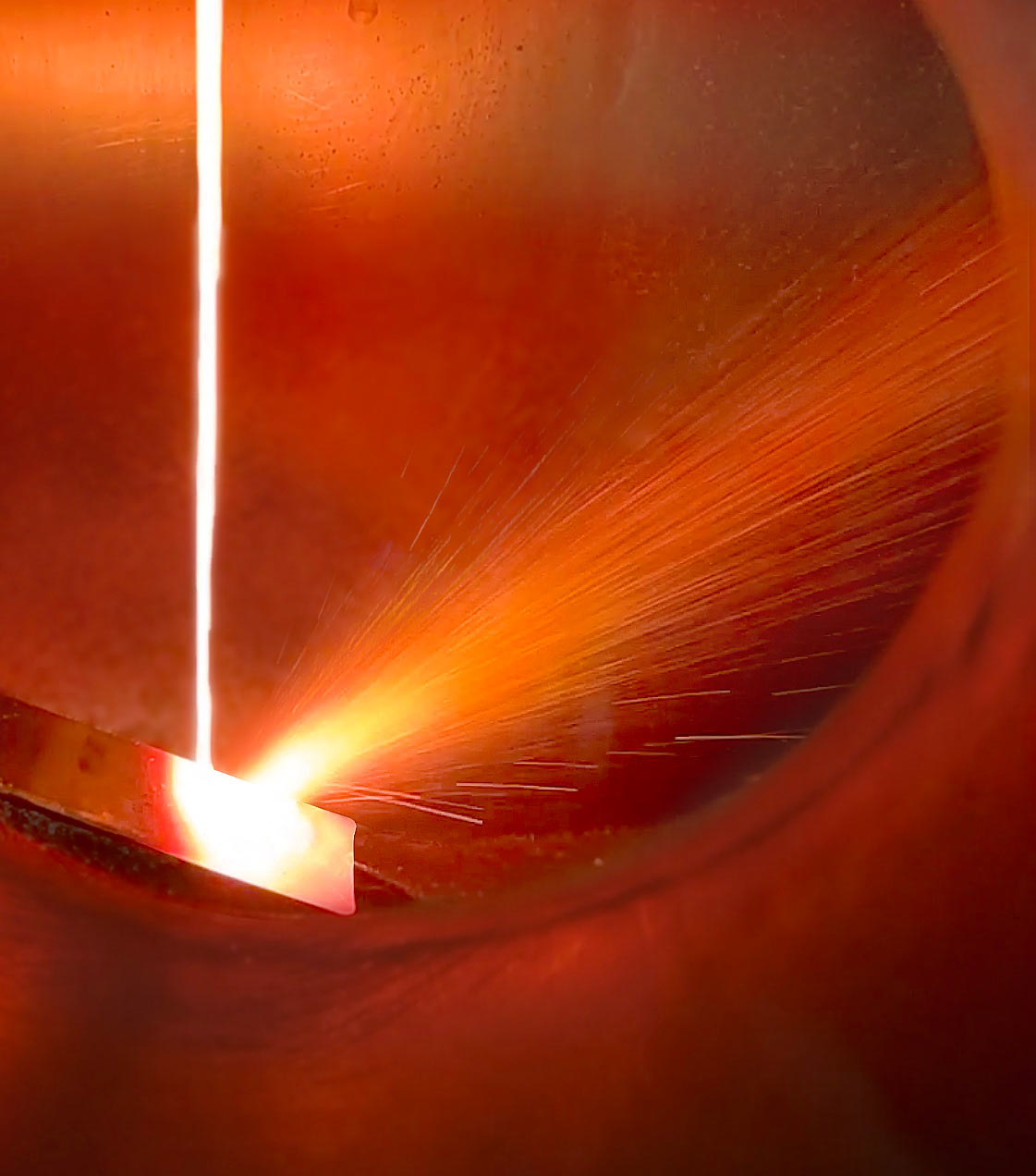

The AUS 500 is available in different batch sizes from 0.25-0.7l. The melting and alloying of the material in the crucible takes place with an indirect induction system (e.g. graphite crucible) or a direct induction system for high temperatures (ceramic crucible).

Data Overview of AUS-Serie

■ standard equipment, ○ optional, - not available| AUS 500 | |

|

Power

|

|

| Generator kw | 10 |

| Temperature max. | 1400° C |

|

Capacity

|

|

| Volume in kg gold (max.) | 10kg AU 18 ct* |

| Volume in kg bronze** | 5,6 |

| Crucible Volume in l* | 0,245 - 0,7 |

*Liquid metal up to top level of the crucible

** Average capacities. Quantity may be increased by optimizing metal load using feeding systems.

*** Option up to 1800°C or even higher in development within a forthcoming EU-funded project.

All machine descriptions and technical data published on this site make no claim to be complete. They are subject to change and therefore they are not basis of contract.

Find more about AUS-Serie

Particle size distribution

To the perfect powder in 4 easy steps