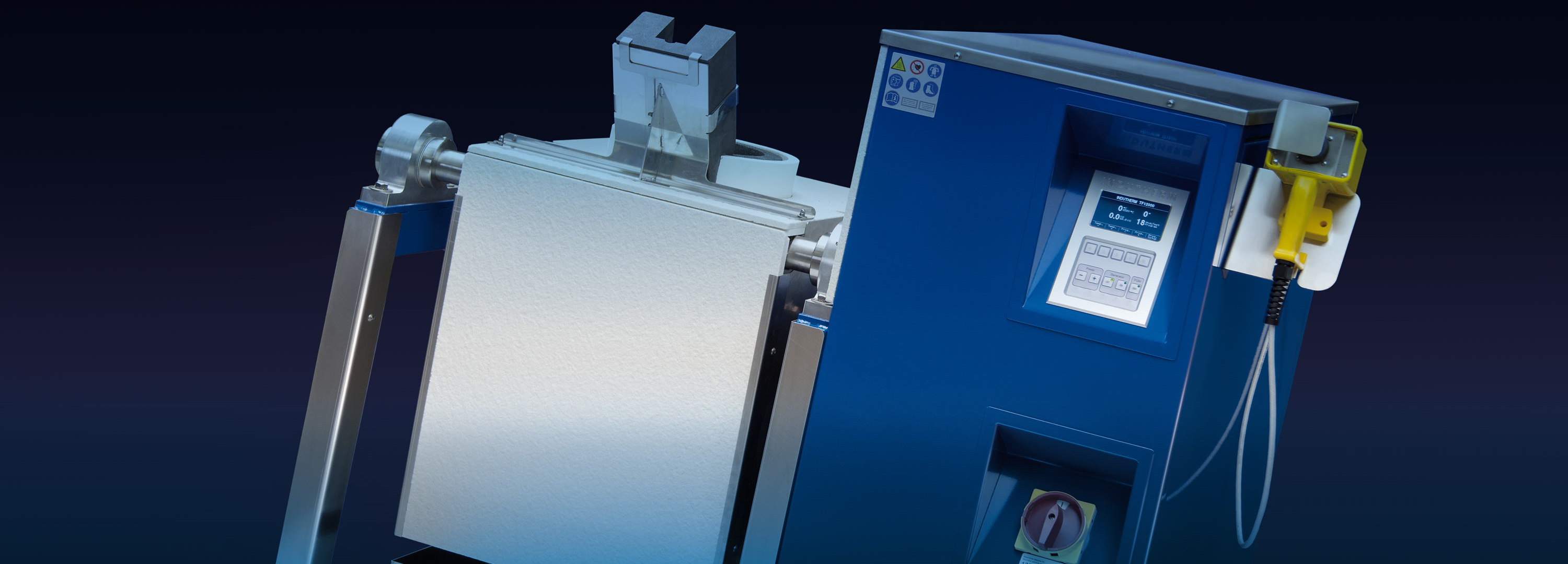

Powerful, efficient and safe

The TF series tilting ovens are equipped with 32-bit induction generators, which depending on the version Deliver output power from 15 to 60 kW. Thanks to the low-frequency design, excellent mixing is achieved even with large quantities. All Versions are controlled via an LCD display with full text display.

Effiziente Wärmedämmung und elektromagnetische Abschirmung sorgen für einen hohen Wirkungsgrad. Von Kunden durchgeführte Vergleichstests haben ergeben, dass die TF 12000 eine höhere Produktivität aufweist als ein Konkurrenzmodell mit der doppelten Leistung und entsprechend doppelten Energiekosten.

Data Overview of TF-Series

■ standard equipment, ○ optional, - not available| TF-2000 | TF-Series | TF-4000 | TF-4000 HTC | TF-6000 | TF-Series | TF-12000 | TF-12000 HTC | TF-28000 | |

|

Power

|

|||||||||

| Power max. / electrical connection | 20 kW (3x400 V) | 20 kW (3x400 V) | 30 kW (3x400 V) | 30 kW (3x400 V) | 40 kW (3x400 V) | 40 kW (3x400 V) | 40 kW (3x400 V) | 60 kW (3x400 V) | 60 kW (3x400 V) |

| Temperature max. | 1500° C | 1850° C | 1500° C | 1850° C | 1500° C | 1850° C | 1500° C | 1850° C | 1500° C |

|

Operation and Control

|

|||||||||

| Control system | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout |

| Programs | 20 | 20 | 20 | 20 | 100 | 100 | 100 | 100 | 100 |

| Tilting by lever | ■ | ■ | ■ | ■ | - | - | - | - | - |

| Tilting with motor drive (remote control) | - | - | - | - | ■ | ■ | ■ | ■ | ■ |

| Temp. measurement by thermocouple | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| Temperature measurement equipped with an optical pyrometer | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

|

Quality Assurance

|

|||||||||

| RS 232, Ethernet, USB interface, diagnostic system | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| GSM-modem for remote service | ○ | ○ | ○ | ○ | ■ | ■ | ■ | ■ | ■ |

|

DMS

|

■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| InduthermCloud | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| iThermControl | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

|

Accesories

|

|||||||||

| Protective gas flush to avoid oxidation | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Vacuum pump | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

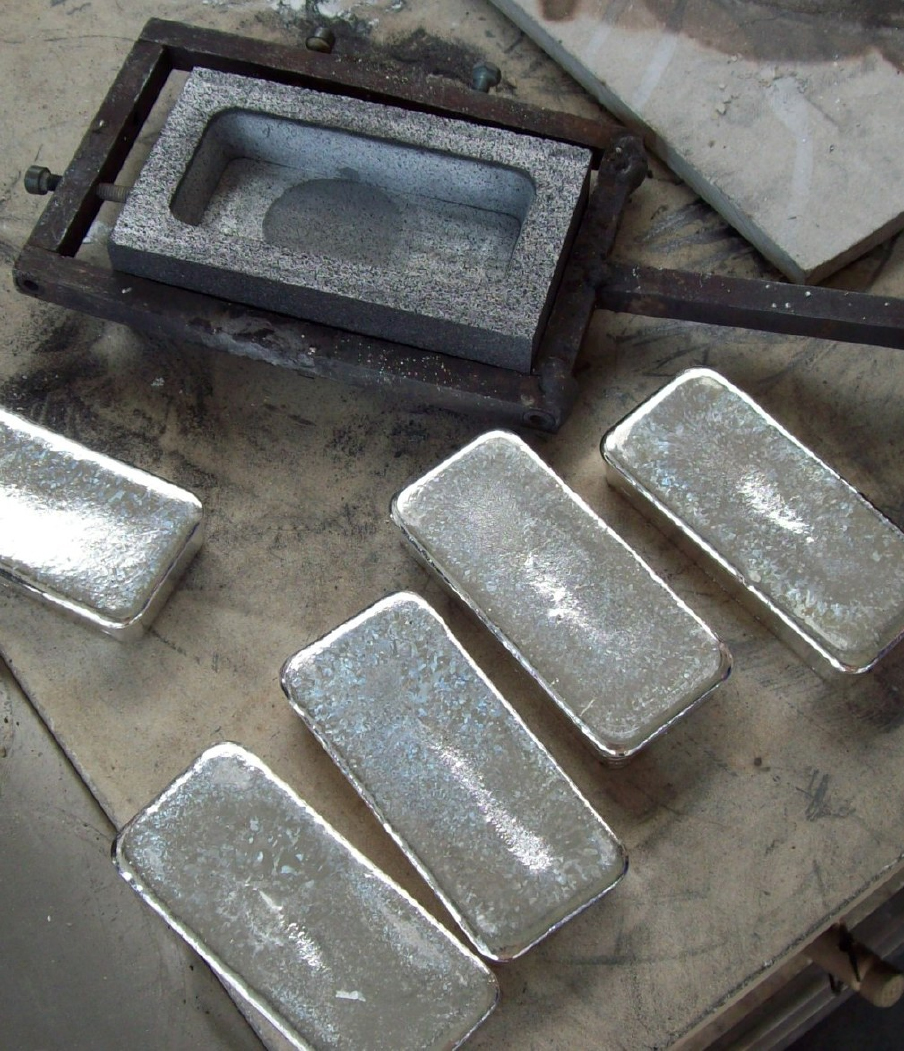

| Moveable table (with customized molds) | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Hood for smoke vent | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

*real capacity for casting / useful volume

All machine descriptions and technical data published on this site make no claim to be complete. They are subject to change and therefore they are not basis of contract.