Our efficient solution for ring and bangle production

The new SU 450 is equipped with a highly sensitive sensor system, which permanently controls the reduction of the rings and provides real-time information about the reduction values on the display. The temperature is regulated automatically and very precisely close to the solidus temperature, exactly until the reduction begins. As soon as the pre-defined reduction value has been reached, the process stops automatically and so too much deformation can be eliminated (depending on composition and alloy the pre-defined reduction value lies between 0.1 mm and 0.3 mm).

"Sensor-Control-System"

The “Sensor-Control-System” considerably reduces the time and material required for the production for two major reasons: firstly because the process parameters can be defined quickly and without making lots of test rings; and secondly because the quality of the sintering process is constantly very high. Therefore the finishing effort is reduced, as well as the loss of material, which occurs during subsequent diamond dressing or turning.

Data Overview of SU 450

■ standard equipment, ○ optional, - not available| SU 450 | SU 450 XL | |

|

Power

|

||

| Temperature max. | 1300° C | 1300° C |

| Power max. / electrical connection | 4,5 kW (3x400 V) | 4,5 kW (3x400 V) |

|

Capacity

|

||

| Sintering processes per hour | ≈ 10 | ≈ 10 |

| Diffusion bonding up to Ø mm | 35 | 70 |

|

Operation and Control

|

||

| Reduction control | ■ | ■ |

| Control system | by LCD-display, full text readout | by LCD-display, full text readout |

| Electronic fix stop | ■ | ■ |

| Automatic process stop | ■ | ■ |

| Programs | 100 | 100 |

|

Quality Assurance

|

||

| RS 232, Ethernet, USB interface, diagnostic system | ■ | ■ |

| Data printer | ■ | ■ |

| GSM-modem for remote service | ○ | ○ |

|

DMS

|

○ | ○ |

| InduthermCloud | ○ | ○ |

| iThermControl | ○ | ○ |

|

Accesories

|

||

| Vacuum pump | ○ | ○ |

| Water chiller | ○ | ○ |

Find more about SU 450

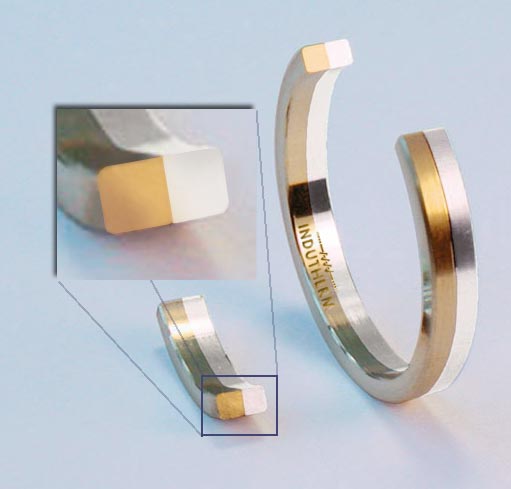

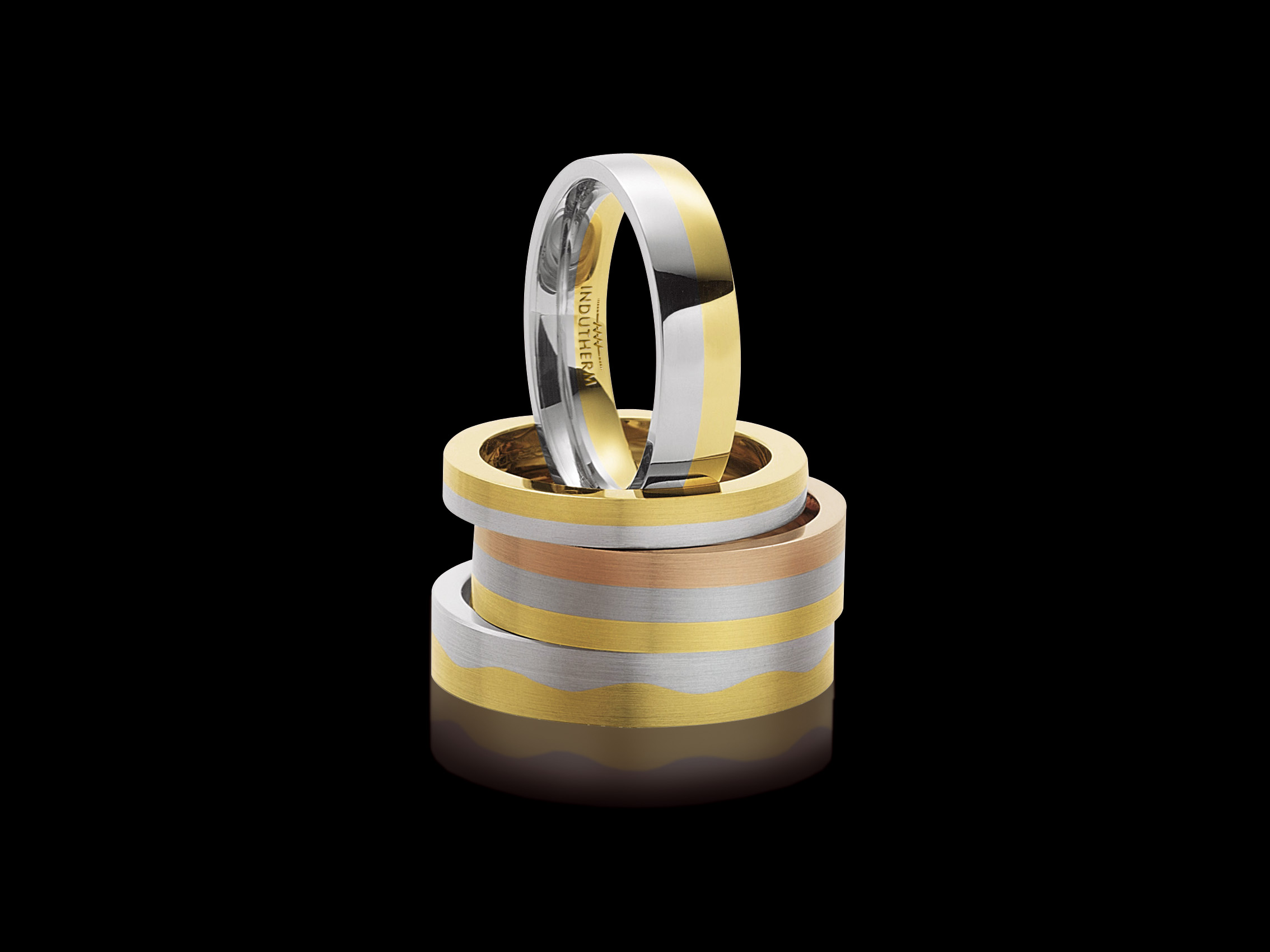

Two different methods of sintering:

Special sintering machines SU 450/SU 450 XL or the sintering kit for installation into existing casting or continuous casting machines.

The Sintering Kit

The sintering kit can be installed into existing VC 400 to VC 680 V type casting machines and in the continuous casting machines. The kit is ideal for the occasional diffusion bonding job and for smaller series production. Only a few minutes are needed to install/remove the sintering kit.

For larger production quantities we recommend our sintering machine SU 450.

Sintering Machines SU 450/SU 450 XL

The SU 450 machines are equipped with a highly sensitive sensor system, which permanently controls the reduction of the rings and provides real-time information about the reduction values on the display. The temperature may be regulated very precisely close to the solidus temperature, right until the reduction begins. As soon as the pre-defined reduction value has been reached, the process stops automatically thus preventing too much deformation (depending on the composition and alloy the pre-defined reduction value varies between 0.1 mm and 0.3 mm). The “Sensor-Control-System” considerably reduces the time and material required for production for two major reasons: firstly because the process parameters can be defined quickly and without making lots of test rings; and secondly because the quality of the sintering process is constantly very high. Therefore the finishing effort is reduced, as well as the loss of material, which occurs during subsequent diamond dressing or turning.

-

SU 450

The new SU 450 is equipped with a highly sensitive sensor system, which permanently controls the reduction of the rings and provides real-time information about the reduction values on the display. The temperature is regulated automatically and very precisely close to the solidus temperature, exactly until the reduction begins. As soon as the pre-defined reduction value has been reached, the process stops automatically and so too much deformation can be eliminated (depending on composition and alloy the pre-defined reduction value lies between 0.1 mm and 0.3 mm).