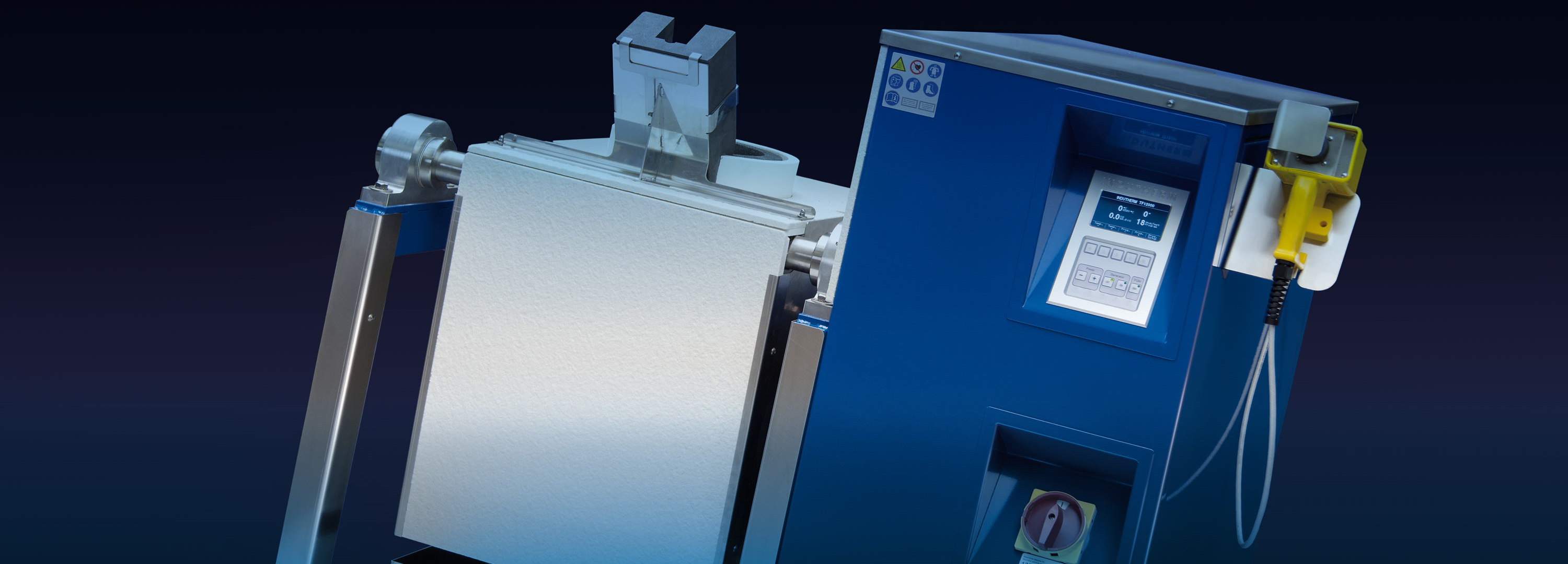

TF-12000 – the giants among the tilting furnaces

The large crucible volumes of 6,000, 12,000 or 28,000 ccm gives these machines an enormous capacity. Because of the potentially large weight, the inductor/ crucible unit is not tilted manually – it uses a motor drive with a stable shaft. Use of a joystick enables the tilting process to be controlled easily and sensitively.

Data Overview of TF-12000

■ standard equipment, ○ optional, - not available| TF-2000 | TF-Series | TF-4000 | TF-4000 HTC | TF-6000 | TF-Series | TF-12000 | TF-12000 HTC | TF-28000 | |

|

Power

|

|||||||||

| Power max. / electrical connection | 20 kW (3x400 V) | 20 kW (3x400 V) | 30 kW (3x400 V) | 30 kW (3x400 V) | 40 kW (3x400 V) | 40 kW (3x400 V) | 40 kW (3x400 V) | 60 kW (3x400 V) | 60 kW (3x400 V) |

| Temperature max. | 1500° C | 1850° C | 1500° C | 1850° C | 1500° C | 1850° C | 1500° C | 1850° C | 1500° C |

|

Operation and Control

|

|||||||||

| Control system | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout |

| Programs | 20 | 20 | 20 | 20 | 100 | 100 | 100 | 100 | 100 |

| Tilting with motor drive (remote control) | - | - | - | - | ■ | ■ | ■ | ■ | ■ |

| Tilting by lever | ■ | ■ | ■ | ■ | - | - | - | - | - |

| Temp. measurement by thermocouple | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| Temperature measurement equipped with an optical pyrometer | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

|

Quality Assurance

|

|||||||||

| RS 232, Ethernet, USB interface, diagnostic system | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| GSM-modem for remote service | ○ | ○ | ○ | ○ | ■ | ■ | ■ | ■ | ■ |

|

DMS

|

■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| InduthermCloud | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| iThermControl | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

|

Accesories

|

|||||||||

| Protective gas flush to avoid oxidation | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Vacuum pump | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

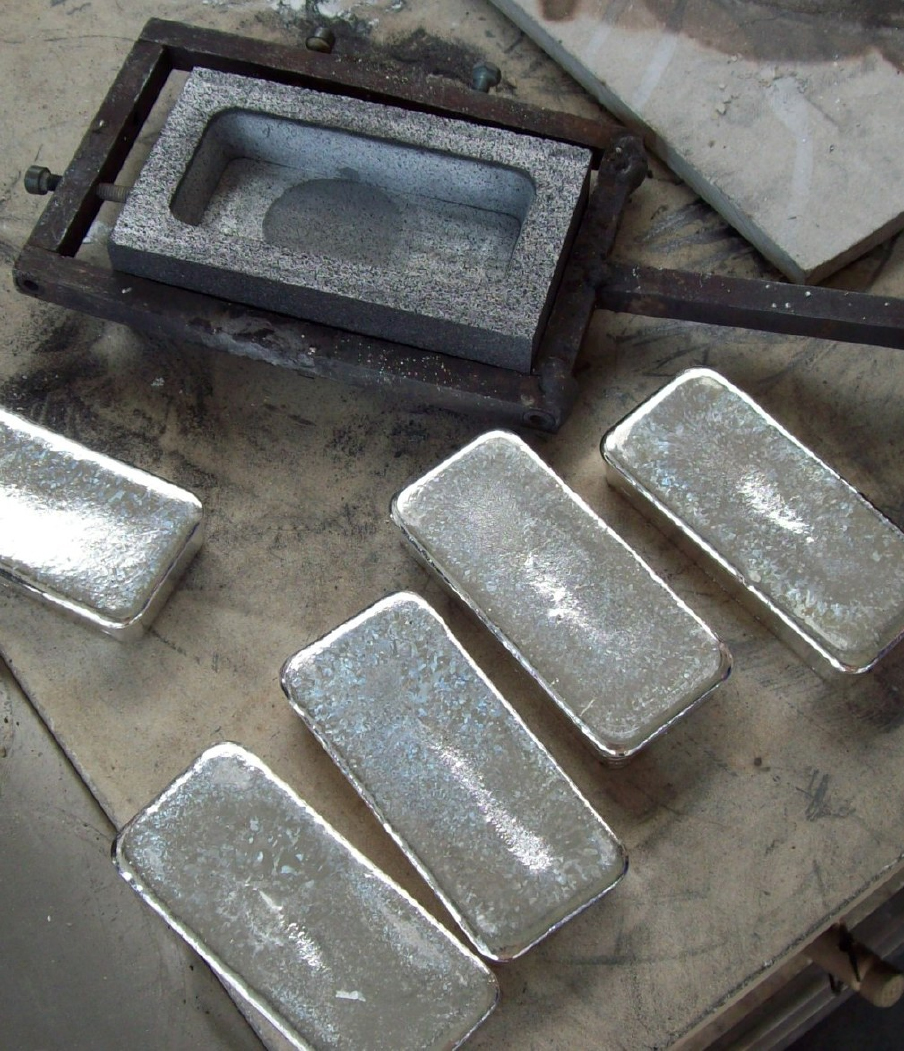

| Moveable table (with customized molds) | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Hood for smoke vent | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

*real capacity for casting / useful volume