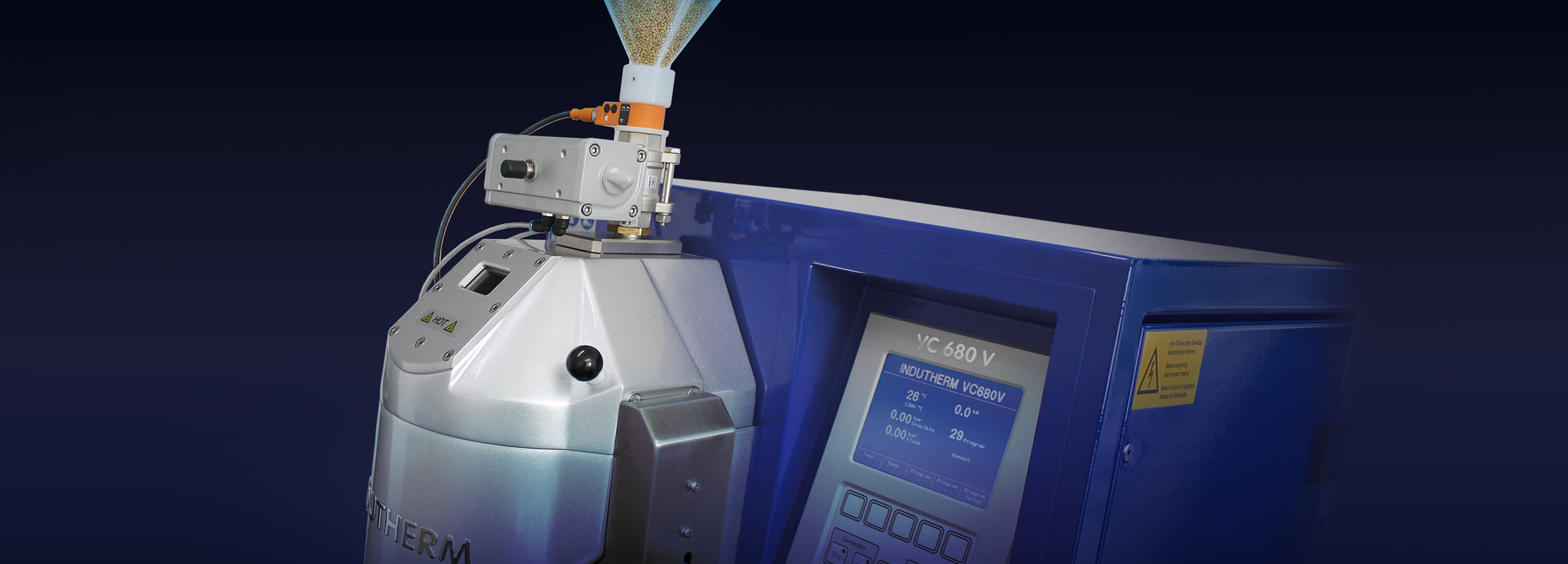

Optimized vibration system plus novel high speed overpressure system

We have developed our new programme-controlled, fully automatic VC 460 V vacuum overpressure casting machine specifically for casting jewellery with embedded stones and for casting intricate shapes.

Firstly, we have optimised the proven Indutherm vibration system: the vibrations, which ensure a higher density, finer grain structure and the lowest possible porosity, are now transmitted even more directly to the casting mould in the ideal frequency range. Secondly, the VC 460 V has an innovative high-speed overpressure system with up to 3 bar overpressure. Together, these two measures enable outstandingly good mould filling, even with very challenging moulds.

AUTO LOCK, the new automatic closing and locking system

The new automatic closing and locking system for the melting chamber closes the lid at the touch of a button and locks it reliably, quickly and gently. This means an enormous increase in convenience and enables an even higher production speed.

And not to forget: The design of the system has been visually and ergonomically optimised and makes the casting system even easier to handle.

And not to forget: The design of the system has been visually and ergonomically optimised and makes the casting system even easier to handle.

Data Overview of VC460V

■ standard equipment, ○ optional, - not available| VC400 | VC450 | VC500 | VC450V | VC460V | VC480V | VC650V | VC680V | VC1000V | VC25000 | VC3000V | VC650VHTC | VC680VHTC | VC1000VHTC | VC12000HTC | VC3000VHTC | |

|

Power

|

||||||||||||||||

| Power max. / electrical connection | 3.5 kW (230 V)|4.5 kW (3x400 V) | 4,5 kW (3x400 V) | 10 kW (3x400 V)|10 kW(3x208 V) | 4,5 kW (3x400 V) | 4,5 kW (3x400 V) | 8 kW (3x400 V) | 12 kW (3x400v) | 12 kW (3x400v) | 20 kW (3x400 V) | 60 kW (3x400 V) | 30 kW (3x400 V) | 12 kW (3x400v) | 12 kW (3x400v) | 20 kW (3x400 V) | 40-60 kW (3x400 V) | 30 kW (3x400 V) |

| Temperature max. | 1400° C | 1600° C | ||||||||||||||

| Temperature max. indirect inductive heating HTC | 1850° C | 1850° C | 1850° C | 1850° C | 2000° C | 2000° C | 2000° C | 1850° C | 2000° C | |||||||

|

Capacity

|

||||||||||||||||

| Crucible Volume | ■ 170 ccm = 2,5 kg Au 18 ct / 1,5 kg Cu* | 170 ccm = 2,5 kg Au 18 ct / 1,5 kg Cu* | ■ 245 ccm = 3,6 kg Au 18 ct / 2 kg Cu* ○ 386 ccm = 5,8 kg Au 18 ct / 3,3 kg Cu* |

170 ccm = 2,5 kg Au 18 ct / 1,5 kg Cu* | 170 ccm = 2,5 kg Au 18 ct / 1,5 kg Cu* | ■ 170 ccm = 2,5 kg Au 18 ct / 1,5 kg Cu* ○ 245 ccm = 3,6 kg Au 18 ct / 2 kg Cu* |

■ 245 ccm = 3,6 kg Au 18 ct / 2 kg Cu* ○ 386 ccm = 5,8 kg Au 18 ct / 3,3 kg Cu* ○ 700 ccm =10,5 kg Au 18 ct / 6 kg Cu* |

■ 245 ccm = 3,6 kg Au 18 ct / 2 kg Cu* ○ 386 ccm = 5,8 kg Au 18 ct / 3,3 kg Cu* ○ 700 ccm =10,5 kg Au 18 ct / 6 kg Cu* |

1,5 l (1,7) = 4 kg Al / 12 kg Cu / 12 kg steel* | 25 l = 65 kg Al / 200 kg Cu* | 3,4 l (3,9) = 8,5 kg Al / 25 kg Cu / 25 kg steel* | ■ 245 ccm = 3,6 kg Au 18 ct / 2 kg Cu* ○ 386 ccm = 5,8 kg Au 18 ct / 3,3 kg Cu* ○ 700 ccm =10,5 kg Au 18 ct / 6 kg Cu* |

■ 245 ccm = 3,6 kg Au 18 ct / 2 kg Cu* ○ 386 ccm = 5,8 kg Au 18 ct / 3,3 kg Cu* ○ 700 ccm =10,5 kg Au 18 ct / 6 kg Cu* |

1,5 l (1,7) = 4 kg Al / 12 kg Cu / 12 kg steel* | 12 l (14 ) = 30 kg Al / 90 kg Cu / 90 kg steel* | 3,4 l (3,9) = 8,5 kg Al / 25 kg Cu / 25 kg steel* |

| For use of molds up to | ø 130 mm / 240 mm h | ø 130 mm / 240 mm h | ■ ø 130 mm / 240 mm h ○ ø 160 mm / 400 mm h |

■ ø 130 mm / 240 mm h ○ ø 160 mm / 400 mm h |

■ ø 130 mm / 240 mm h ○ ø 160 mm / 400 mm h |

■ ø 130 mm / 240 mm h ○ ø 160 mm / 400 mm h |

ø 250 mm / 500 mm h | ø 600 mm / 800 mm h | ø 450 mm / 600 mm h | ■ ø 130 mm / 240 mm h ○ ø 160 mm / 400 mm h |

■ ø 130 mm / 240 mm h ○ ø 160 mm / 400 mm h |

ø 250 mm / 500 mm h | ø 600 mm / 800 mm h | ø 450 mm / 600 mm h | ||

| For use of molds | up to ø 130 mm / 240 mm h | ■ up to ø 130 mm / 240 mm h ○ bis ø 160 mm / 400 mm h | ||||||||||||||

|

Operation and Control

|

||||||||||||||||

| Dual temperature control | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ■ | ■ | ■ | ○ | ○ | ■ | ■ | ■ |

| Automatic mold and chamber lift | ■ | - | ■ | - | - | ■ | ■ | ■ | ■ | ■ | ||||||

| Turbo Pressure Function | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| Maximum pressure | ■ up to 1,5 bar ○ up to 3,0 bar | ■ up to 1,5 bar ○ up to 3,0 bar | ■ up to 1,5 bar ○ up to 3,0 bar | ■ up to 1,5 bar ○ up to 3,0 bar | ■ up to 1,5 bar ○ up to 3,0 bar | ■ up to 1,5 bar ○ up to 3,0 bar | 3 bar | 3 bar | 0,5 bar | 0,3 bar | 0,3 bar | 3 bar | 3 bar | 0,5 bar | 0,3 bar | 0,3 bar |

| Control system | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout |

| Automatic bell lock | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| Mold temperature measurement | - | - | - | - | ■ | ■ | ■ | ■ | ||||||||

| Automatic mold and chamber lift | ■ | ■ | ■ | ■ | ■ | ■ | ■ | - | ■ | ■ | ■ | ■ | - | ■ | ||

| HSC (High Speed Casting) feature | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||

| Turbo Pressure PLUS system | - | - | - | ○ | ■ | ■ | ■ | ■ | ||||||||

| Automatic feeding system w/ autom. sealing rod | - | - | - | - | - | ■ | - | ■ | ||||||||

| Vibration technology | - | ■ | - | ■ | standard equipment Sweep Mode | standard equipment Sweep Mode | ■ | ■ | ■ | standard equipment Sweep Mode | standard equipment Sweep Mode | ■ | ■ | ■ | ||

| Automatic closing system | - | - | - | - | ■ | ■ | ■ | ■ | ||||||||

| Programs | 20 | 20 | 20 | 20 | 20 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Mold temperature measurement | ■ | ■ | ||||||||||||||

| Temp. measurement by optical pyrometer | 1400° C | 1400° C | 1400° C | 1600° C | 1700° C | 1700° C | 1500° C | 1300° C | 1500° C | 1700° C | 1700° C | 1500° C | 1300° C | 1500° C | ||

| Turbulence reduction software | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

|

Quality Assurance

|

||||||||||||||||

| RS 232, Ethernet, USB interface, diagnostic system | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| Data printer | - | ○ | - | ○ | ○ | ○ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| GSM-modem for remote service | ○ | ○ | ○ | ○ | ○ | ○ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

|

DMS

|

■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| InduthermCloud | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ■ | ○ | ○ | ○ | ○ | ■ | ○ | ○ | ○ |

| iThermControl | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ■ | ○ | ■ | ||||||

|

Accesories

|

||||||||||||||||

| Sintering / diffusion bonding kit | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||

| Granulation tank | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Granulation tank with flake option | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Vacuum pump | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Water chiller | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Also available as granulating unit | - | GU 500 | ||||||||||||||

* flüssiges Metall bis Tiegeloberkante

** mit zusätzlichem Gastank für Turbo Pressure PLUS

Die auf dieser Seite veröffentlichten Maschinenbeschreibungen und technischen Daten erheben keinen Anspruch auf Vollständigkeit. Sie können sich im Zuge der Weiterentwicklung ändern und sind deshalb keine Vertragsgrundlage.Other Advantages of VC460V

Longer consumable life can be achieved by reducing frequent temperature changes and exposure to oxygen as much as possible. For this reason, we offer filling devices for numerous system models that enable recharging without loss of temperature and without contact with oxygen.

Our self-developed generators and induction heating systems tailored to the intended use ensure maximum energy efficiency. They not only reduce power consumption, but also increase the heating speed and the maximum temperature. They also reduce electromagnetic emissions with regard to the EMC directive. Efficient encapsulation ensures that the induction generated is used with as little loss as possible for rapid melting of the metal. The thermal insulation around the inductor and crucible protects against heat radiation. This high use of energy also reduces the energy consumption for water recooling in the machine and for any air conditioning that may be necessary in the foundry.

Program control system for fast and certified casting processes.

Thanks to the control panel with full text LCD display, all programs and parameters are very easy and convenient to set. The semi-automatic machines offer temperature programs. The fully automatic machines have a program control system involving all parameters. Up to 100 casting programs guarantee fast operation and consistent casting results. Parameters are pre-programmed for all major alloys, e.g. for AGS, Alpha Plus, Heraeus, Legor and Pandora alloys. In practice this means: from the first mold, you can expect good casting results without carrying out expensive pre-tests.

The program control and the integrated data printer ensure a high level of safety and the possibility of precise process documentation (important for certified casting processes).

All Indutherm VC machines have separate lock systems for the melting chamber and mold chamber. This allows time to be saved by “overlapping” casting: while the mold remains in the vaccuum chamber for several minutes after the casting, you may fill in and heat up the next charge.

The filling device means there is no need to open the melting chamber for refilling. This way, the melting chamber temperature remains high and unnecessary loss of energy is avoided. Most importantly: No oxygen enters the melting chamber so the chamber does not need to be evacuated again and refilled with inert gas.

The advantages:

lower personnel costs,

more consistent casting quality,

better process stability, less waste,

optimised overlapping casting,

up to 20 casting cycles per hour,

high energy efficiency,

longer service lives for consumables,

minimised metal loss,

replenishment without loss of pressure.

Numerous measures in our casting systems reduce metal losses during the casting process to an absolute minimum. These include, among other things, the sophisticated overpressure and vacuum controls, the anti-oxidation system, the vibration system and, last but not least, the high-quality materials of the crucibles and sealing rods.

Up to 20 casting cycles per hour thanks to programmable overlapping casting and optional automatic feeding devices.